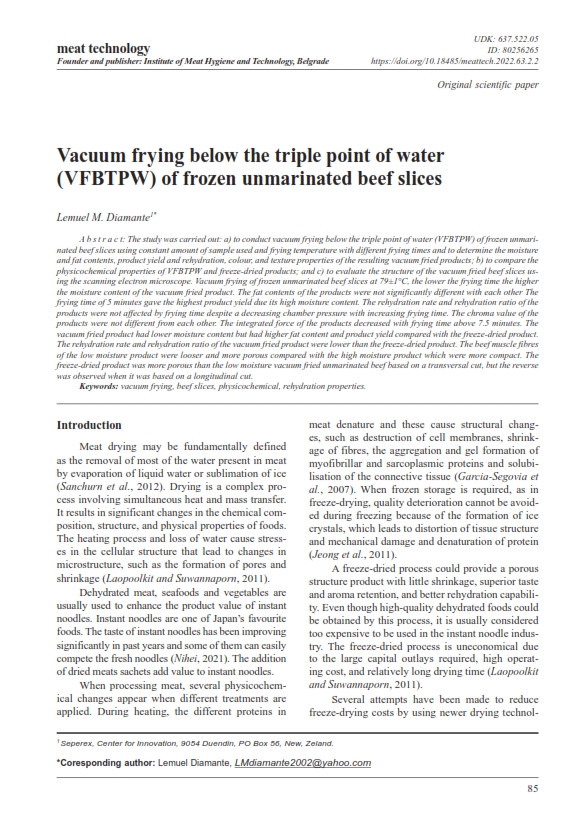

Vacuum frying below the triple point of water (VFBTPW) of frozen unmarinated beef slices

Abstract

The study was carried out: a) to conduct vacuum frying below the triple point of water (VFBTPW) of frozen unmarinated beef slices using constant amount of sample used and frying temperature with different frying times and to determine the moisture and fat contents, product yield and rehydration, colour, and texture properties of the resulting vacuum fried products; b) to compare the physicochemical properties of VFBTPW and freeze-dried products; and c) to evaluate the structure of the vacuum fried beef slices using the scanning electron microscope. Vacuum frying of frozen unmarinated beef slices at 79±1oC, the lower the frying time the higher the moisture content of the vacuum fried product. The fat contents of the products were not significantly different with each other The frying time of 5 minutes gave the highest product yield due its high moisture content. The rehydration rate and rehydration ratio of the products were not affected by frying time despite a decreasing chamber pressure with increasing frying time. The chroma value of the products were not different from each other. The integrated force of the products decreased with frying time above 7.5 minutes. The vacuum fried product had lower moisture content but had higher fat content and product yield compared with the freeze-dried product. The rehydration rate and rehydration ratio of the vacuum fried product were lower than the freeze-dried product. The beef muscle fibres of the low moisture product were looser and more porous compared with the high moisture product which were more compact. The freeze-dried product was more porous than the low moisture vacuum fried unmarinated beef based on a transversal cut, but the reverse was observed when it was based on a longitudinal cut.